As sustainability becomes a central concern in construction and remodeling, understanding the environmental impact of materials like engineered quartz stone is crucial. Here’s how the production of engineered quartz stacks up in terms of environmental sustainability.

Resource Use: Engineered quartz combines natural quartz, which is abundantly available, with synthetic resins. While quartz mining does impact the environment, it is less disruptive compared to the extraction processes for many other stones. The resins, however, are petroleum-based, which raises concerns about fossil fuel consumption and chemical use.

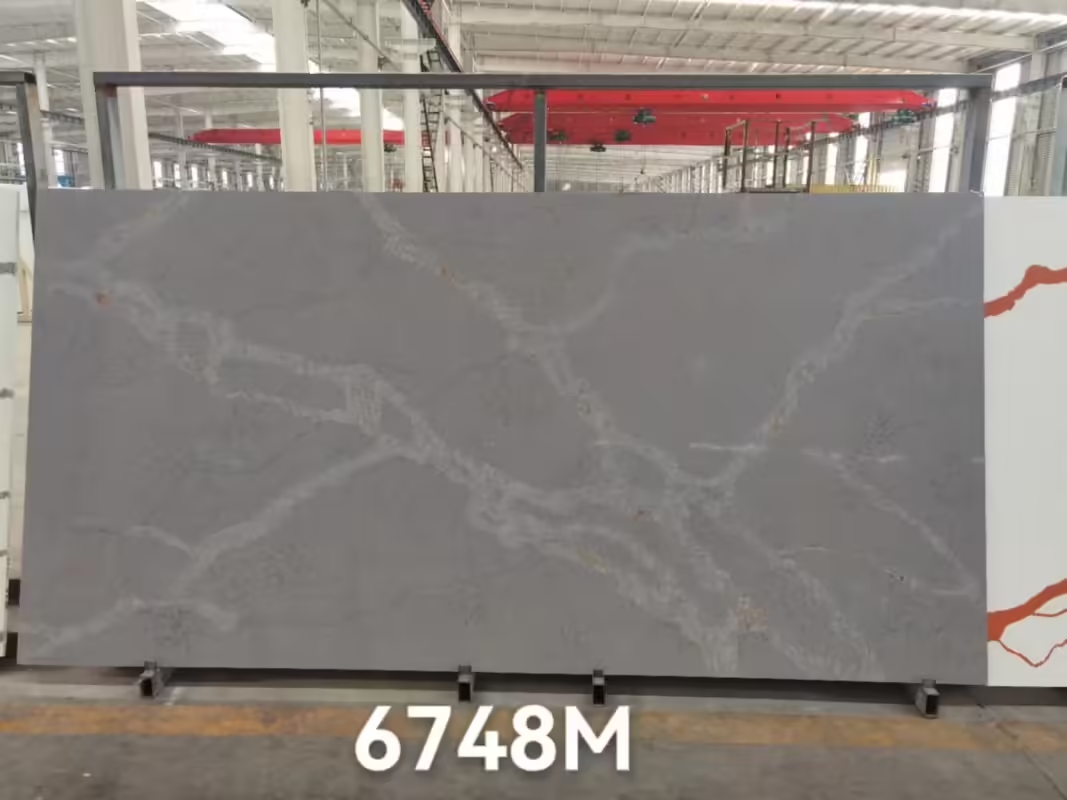

Manufacturing Process: The production of engineered quartz requires significant energy, primarily for powering machinery that crushes, mixes, and compresses the components into slabs. Innovations in manufacturing technology are focusing on reducing these energy needs.

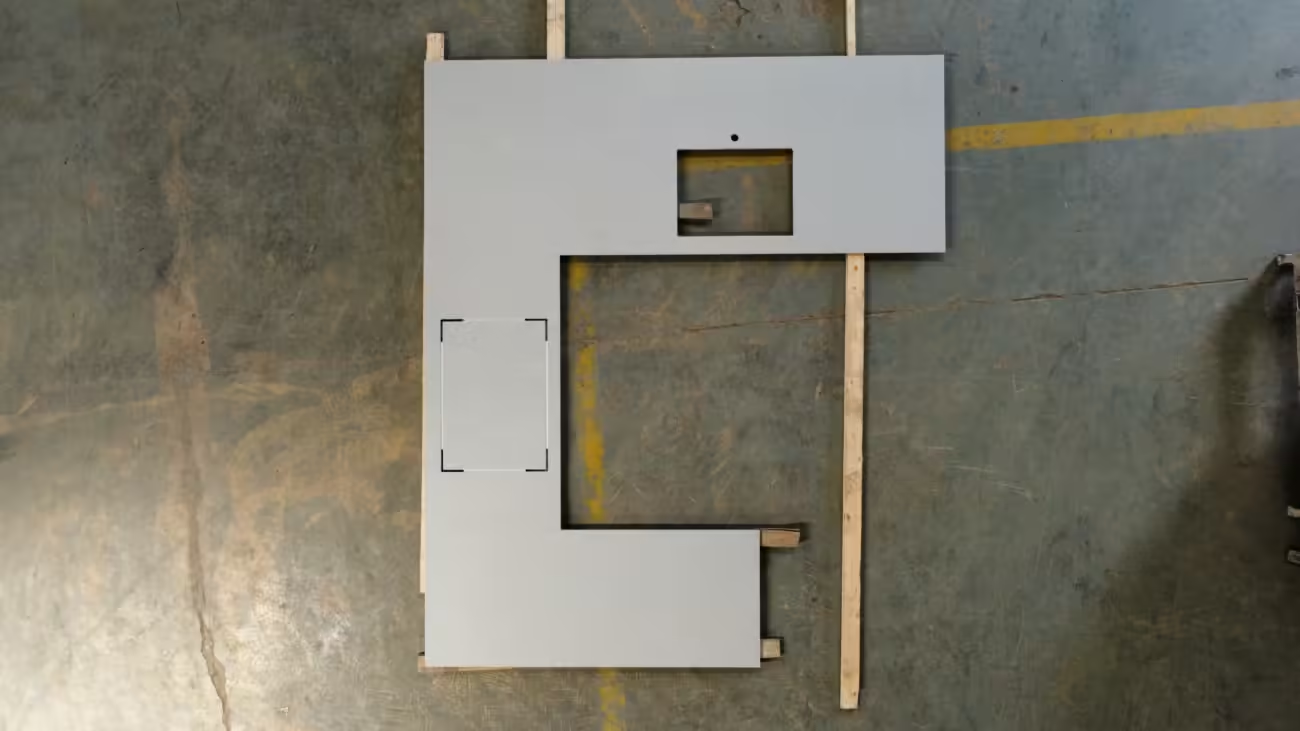

Waste Production: Engineered quartz production generates less natural waste compared to natural stone, which has a high rate of unusable material due to its irregular shapes and flaws. However, the chemical components of engineered stone can make recycling and disposal more problematic.

Longevity and Maintenance: The durability and low maintenance requirements of engineered quartz reduce the need for replacements and harsh cleaning chemicals, contributing positively to its lifecycle sustainability.

Conclusion: While engineered quartz production does have an environmental footprint, ongoing advancements in manufacturing techniques and materials are improving its sustainability profile. For consumers interested in both modern aesthetics and environmental responsibility, engineered quartz offers a compelling option.